Using 3D printed guides for custom piercings allows you to achieve precise, personalized results safely. These guides are designed from detailed scans of your anatomy and serve as exact templates for placement, angle, and depth. They reduce guesswork and help prevent misplacement or injury. By ensuring consistency and accuracy, these guides make the piercing process safer and more aesthetic. Keep exploring to discover how this innovative technology can transform your piercing experience.

Key Takeaways

- 3D printed guides enable precise, customized placement for aesthetic and safety outcomes in piercing procedures.

- They are created from detailed scans and tailored designs to fit individual anatomy perfectly.

- Made from biocompatible, sterile materials, these guides ensure safe application and accurate piercing depth and angle.

- Guides streamline the procedure by providing exact templates, reducing guesswork and minimizing injury risk.

- Digital workflows allow quick adjustments and reprints, enhancing personalization and overall accuracy in custom piercings.

3D printed guides are revolutionizing how custom piercings are planned and performed. When you’re considering a piercing, accuracy is vital—not just for aesthetics but also for safety. That’s where piercing precision becomes essential. Using 3D printing techniques, professionals can create highly detailed, customized guides tailored to your anatomy. These guides serve as precise templates, ensuring every piercing aligns perfectly with your desired location and angle, minimizing the risk of misplacement or injury.

With traditional methods, estimations and experience often determine placement, which can lead to inconsistencies. Now, with 3D printing techniques, the process is more scientific and personalized. Your piercer can start by taking detailed scans or measurements of your anatomy. Then, they use specialized software to design a guide that fits your unique features exactly. The 3D printed guide acts as a roadmap—an exact replica of your anatomy that indicates the perfect spot and angle for the piercing. This level of customization boosts confidence—both for you and your piercer—because it reduces guesswork and increases the likelihood of achieving the ideal aesthetic outcome.

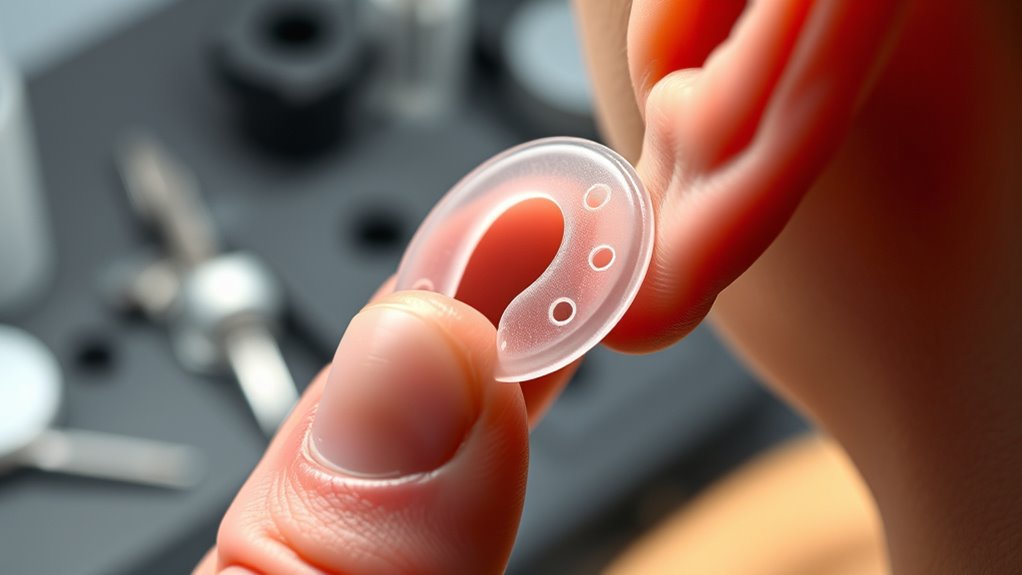

The use of 3D printing techniques also speeds up the planning process. Once the digital design is finalized, it can be printed quickly and with high accuracy. The materials used are biocompatible and sterile, making the guides safe for application directly on your skin. When it’s time for the procedure, your piercer fits the guide onto your ear, nose, or other areas, and the piercing is performed through precise openings in the guide. This method ensures the piercing is exactly where it’s intended to be, at the right depth and angle, every time.

Another advantage is consistency. If you’re getting multiple piercings or touch-ups, 3D printed guides help duplicate the same placement with ease. This consistency is especially valuable for professional piercers aiming for symmetrical, balanced results. Plus, the digital design allows for easy adjustments. If you decide to change the placement slightly, modifications can be made quickly to the 3D model, and a new guide can be printed in a short time.

Ultimately, using 3D printed guides elevates the entire piercing experience. It combines cutting-edge technology with precision craftsmanship, offering a safer, more accurate, and personalized approach. Whether you’re after a simple lobe piercing or a complex cartilage design, these guides help guarantee your vision becomes reality with minimal risk, thanks to the power of advanced 3D printing techniques.

Frequently Asked Questions

Are 3D Printed Guides Reusable for Multiple Piercings?

Yes, 3D printed guides can be reusable if they follow proper sterilization protocols and have a reusable design. You should clean and sterilize the guide thoroughly between uses to prevent infection. Always check if the material supports repeated sterilization without degrading. A reusable design allows you to use the guide multiple times, but ensure you adhere to manufacturer guidelines and sterilization standards for safety and effectiveness.

How Long Does It Take to Produce a Custom 3D Printed Guide?

It typically takes about 24 to 48 hours to produce a custom 3D printed guide, depending on design accuracy and complexity. You’ll want to provide precise specifications to guarantee the guide fits perfectly. Once the design is finalized, the production time begins, involving printing and post-processing. This quick turnaround helps you get your custom piercing guide promptly, ensuring a smooth and accurate piercing experience.

What Materials Are Used in 3D Printed Piercing Guides?

You primarily use biocompatible, medical-grade plastics, resins, or nylons for 3D printed piercing guides. These materials guarantee safety, durability, and comfort, aligning with your focus on material safety. With design customization, you can tailor each guide to fit perfectly, creating a seamless experience. These options allow you to prioritize safety while achieving precise, personalized piercings, making each procedure both safe and uniquely suited to your style.

Can 3D Printed Guides Accommodate Complex or Unusual Piercings?

Yes, 3D printed guides can accommodate complex or unusual piercings. You can customize them based on your unique anatomy considerations, guaranteeing precise placement. These guides also enable aesthetic customization, allowing you to achieve your desired look even with intricate piercing designs. By working closely with your piercer, you ensure the guide fits perfectly, making complex piercings safer and more accurate while catering to your specific anatomy and aesthetic preferences.

What Are the Sterilization Procedures for 3D Printed Guides?

Investigating sterilization protocols reveals they’re vital for contamination prevention when using 3D printed guides. You should clean the guides thoroughly with soap and water, then use an autoclave or chemical sterilants suitable for the material. Make sure all surfaces are sanitized and dry before use. Regularly check sterilization equipment for effectiveness, and follow manufacturer instructions to maintain safety and hygiene during the piercing procedure.

Conclusion

So, next time you’re craving a “unique” piercing, just whip out your 3D printer and design a custom guide—because nothing screams individuality like a precisely manufactured, scientifically perfect hole. Who needs the finesse of a professional piercer when you can DIY with plastic and a dash of misguided confidence? Just remember, if your new “artistic” piercing goes awry, blame the technology, not your questionable design skills. Happy piercing, trendsetter!