Ultrasonic placement tools help you achieve precise, single-pulse piercing with minimal effort and collateral damage. They use high-frequency vibrations to carefully focus energy, making it easier to penetrate delicate or tough materials efficiently. This technology reduces manual force and improves outcomes by delivering clean, consistent penetrations. With proper calibration and quality control, these tools guarantee reliability and ideal results across various applications. Keep exploring to discover more about how this innovative technology can benefit your projects.

Key Takeaways

- Ultrasonic tools enable precise, single-pulse piercing by focusing high-frequency vibrations for efficient material penetration.

- Proper calibration and quality control ensure consistent, accurate results with minimal collateral damage.

- They reduce manual effort and invasive procedures, improving biomechanical stability and longevity.

- Advanced engineering allows these tools to operate reliably under demanding manufacturing and medical conditions.

- Their focused energy minimizes cracking and deformation, facilitating clean, efficient penetrations in delicate or tough materials.

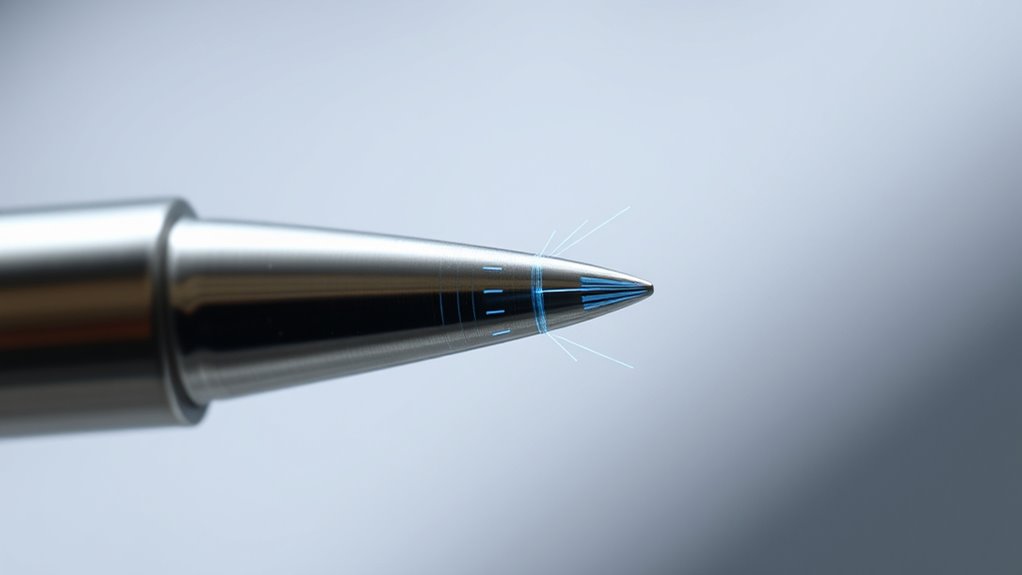

Ultrasonic placement tools have revolutionized how professionals position and install various materials, offering precise and efficient results. These tools harness high-frequency vibrations to pierce, cut, and place materials with minimal effort, reducing overall procedure time and improving accuracy. When you use ultrasonic technology, you gain a significant advantage in achieving consistent, clean penetrations in even the most delicate or tough materials. This precision stems from the tool’s ability to focus energy exactly where it’s needed, minimizing collateral damage and guaranteeing ideal placement. As a result, your work benefits from higher biomechanical advantages, such as improved integration, stability, and longevity of the installed components.

Ultrasonic tools deliver precise, efficient material placement with minimal effort and collateral damage.

You’ll find that ultrasonic placement tools excel at overcoming many manufacturing challenges. Traditional methods often involve manual force, multiple steps, or invasive techniques that can compromise material integrity or lead to inconsistent results. Ultrasonics streamline these processes, enabling you to achieve a single, clean piercing in one pulse. This reduces the risk of material cracking or deformation, which can be common with conventional approaches. Moreover, these tools are adaptable across a range of applications, from medical implants to industrial assembly lines, making them invaluable in settings where precision and speed matter most. Additionally, the development of these tools involves sophisticated engineering to ensure durability and performance under demanding conditions.

Despite their advantages, you should be aware of some manufacturing challenges associated with ultrasonic placement tools. Developing these devices requires advanced engineering to guarantee durability and consistent performance under demanding conditions. Components must withstand high-frequency vibrations without degrading, which demands high-quality materials and meticulous manufacturing processes. Additionally, integrating ultrasonic transducers with ergonomic design can be complex, as they need to deliver powerful, focused energy while remaining user-friendly. This often involves balancing miniaturization with robustness and ensuring the device’s reliability over extended periods of use.

Another challenge is the calibration and maintenance of ultrasonic tools. To maintain their precision and biomechanical benefits, regular calibration and quality control are essential. Manufacturing these tools at scale involves strict adherence to specifications, often requiring sophisticated testing and quality assurance procedures. While these challenges can be significant, they’re also opportunities for innovation. Manufacturers continually refine their processes to produce more reliable, cost-effective ultrasonic placement tools that meet the high standards required in demanding industries. Proper calibration procedures are crucial for sustaining optimal performance over time.

In the end, your ability to leverage ultrasonic placement tools depends on understanding both their biomechanical advantages and the manufacturing challenges involved. When these factors are managed well, you can achieve single-pulse, precise penetrations that enhance your project’s quality and efficiency. This technology not only simplifies complex procedures but also elevates the standards for material placement, making it an indispensable part of modern manufacturing and medical procedures.

Frequently Asked Questions

What Materials Can Ultrasonic Placement Tools Pierce Effectively?

When considering ultrasonic placement tools, you wonder what materials they can pierce effectively. You’ll find that material compatibility varies; these tools work best on metals like titanium and stainless steel, as well as certain plastics. To guarantee success, you should prepare surfaces properly—clean and smooth surfaces improve efficiency. With proper surface prep and understanding material compatibility, you’ll achieve precise, single-pulse piercing, making your work faster and more accurate.

How Do Ultrasonic Tools Compare to Traditional Piercing Methods?

You’ll find ultrasonic tools offer notable advantages over traditional piercing methods. They utilize ultrasonic energy efficiency to create precise, clean piercings with minimal tissue damage. Plus, their piercing speed comparison is impressive; they can complete procedures faster while maintaining accuracy. This means less discomfort for you and quicker healing times. Overall, ultrasonic tools provide a more efficient, gentle, and precise approach to piercing compared to conventional techniques.

Are There Safety Concerns With Ultrasonic Piercing Tools?

You might think ultrasonic piercing tools are as dangerous as a lightning strike, but with proper safety protocols and operator training, they’re very safe. These tools minimize tissue damage and reduce infection risks when used correctly. Always follow safety guidelines, wear protective gear, and make certain operators are well-trained. When handled properly, ultrasonic tools provide precise, safe piercing experiences without the hazards associated with traditional methods.

What Is the Typical Lifespan of an Ultrasonic Placement Tool?

You might wonder about the typical lifespan of ultrasonic placement tools. Generally, these tools are quite durable, with proper maintenance extending their life. Their tool durability depends on usage frequency and adherence to maintenance requirements, like regular cleaning and calibration. By following manufacturer guidelines and performing routine checks, you can guarantee your ultrasonic tools stay in peak condition, maximizing their longevity and performance over time.

Can Ultrasonic Tools Be Used for Medical or Industrial Applications?

Imagine a tool that harnesses ultrasonic energy like a symphony of tiny vibrations. You’ll find ultrasonic tools excel in medical and industrial applications because of their precision and versatility. They work with various materials, but material compatibility is key. These tools can cut, weld, or clean, making them invaluable across fields. Their ability to perform delicate tasks with accuracy makes ultrasonic tools a essential part of modern technology.

Conclusion

With ultrasonic placement tools, you achieve precision with a single pulse—like a painter’s brushstroke, swift and exact. Yet, beneath that simplicity lies complex technology working tirelessly, much like an orchestra’s silent conductor. This juxtaposition of effortless results and intricate mechanics reminds you that innovation often hides in the smallest details. So, as you leverage these tools, remember: it’s the perfect harmony of simplicity and sophistication that drives success.